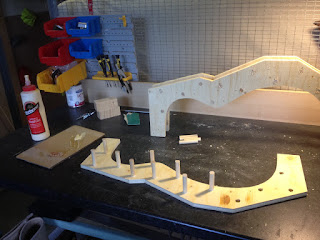

I've also cut the pre-curved sides to length and fitted the end and top blocks to join them together.

It's beginning to dawn on me that a workshop can never have too many clamps. Some of these were borrowed from hubby's engineering workshop. I will build up my own collection in time. Especially as clamps borrowed from a metal working workshop need considerable cleaning up before they can be used anywhere near wood.

Here is the rim in the jig ready for the kerfling to be fitted. The kerfling gives the top and back something to adhere to that is thicker than the 2mm sides.

There are specialist clamps available for this process but (despite my earlier comments about clamps) the common clothes peg works just as well.

The next tasks are to complete fixing the kerfling (blogger has come up with some very funny alternatives for the word 'kerfling' which apparently doesn't exist) then onto designing the new sound hole rosette.

Tune in soon for the next thrilling instalment! ;)

No comments:

Post a Comment