So, where has GBG been?

I'm sure my avid readers (all three of you) have been wondering about

the progress of the black guitar.

Well, as I have now

explained to M why his guitar has been delayed and decided that it's

not really good enough to only blog the good parts of the project I

will explain.

The black finish is

proving very tricky, to say the least. On my first attempt I

installed the rosette first and polished it up before applying the

stain, knowing it would scrape off the rosette componants.

Unfortunately, in polishing the rosette I damaged the grain of the

spruce. This was only evident once the black stain was applied

because the timber around the sound hole wouldn't take the stain in

the same way as the the rest of the top. After several attempts to

fix this I also realised that getting the finish back off the rosette

was much harder than I had thought. So, I started again. I routed the

green malachite back out of the top and put it aside.

I stained and finished

top number 2 before routing it. I planned to create the rosette in

another piece of board, polish it and then insert it in the new top

complete. The finish came out very well. Then whilst routing the

rings (and despite taking every precaution I could think of, vacuum

suction, masking tape, sheets of paper between all surfaces) I

managed to scratch the black top. I may have become a little

frustrated at this point!

ᕙ(⇀‸↼‶)ᕗ

I also googled for any

tips from fellow luthiers who have completed similar projects. In the

top 3 search results was MY OWN BLOG! I'm sure there's a moral there

somewhere...

So, after trying to

repair the top and failing I completed the routing, removed the

finish and started the finishing process AGAIN this time with the

routed circle in place. I used the same set-up on the circle cutter

to rout a channel in which to create the rosette for installation as

a complete unit.

At present the rosette

is complete and ready to be inserted once the top finish is complete.

I have to leave it 48 hours between coats of finish so it's taking

sometime to prepare.

I am hoping the

mahogany back and sides will be rather easier to finish, they at

least don't have a rosette to worry about!

As for future projects

I think I will stick to natural coloured guitars unless the customer

can be persuaded that a 'distressed' finish is the height of cool. So

don't worry M, when you finally get your black guitar it will truly

be one of a kind.

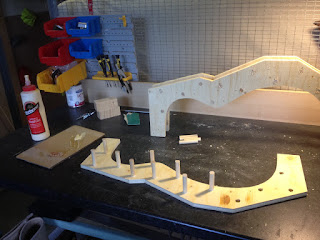

On the positive side I

have completed the fret-board fox inlay. When the guitar has a body

I'm sure this little fox will set it off beautifully.

In other news, I am

just putting the final touches to my second album. Perhaps

surprisingly it does not contain a song called 'Black Guitar Blues'.

Maybe for album three...